Improving Manufacturing Techniques to Deliver High-Quality Biotherapeutics to the Clinic Faster

An Accelerated Drug-Development Journey

January 2, 2021

Biologics — medical therapies derived from living organisms, such as cellular proteins, DNA or RNA — have improved treatments significantly for many diseases, including vaccines and treatments for cancers and autoimmune diseases. Although the use of cellular or gene-based medicines can be advantageous as a targeted therapy, the ability to manufacture biologics of high quality and in mass quantity is very difficult and costly.

Because batches can vary slightly in structure, strict monitoring and testing are needed to ensure the same function and safety profile. But the current testing systems can be cumbersome, further hampering the throughput and real-time protein analytics that today’s rapidly growing biopharmaceutical industry needs for its drug development and manufacturing efforts. An analytical system to detect and analyze proteins rapidly would streamline biologics production and could lead to reduced development and production costs, improved quality and compliance, and better therapies tailored to patient needs — and ultimately, to greater accessibility for more people.

Intabio, Inc., a Silicon Valley–based company that received funding from NCATS through the Small Business Innovation Research (SBIR) program, set out to create a solution that would quickly and accurately determine a biologic’s characteristics and detect crucial changes to the molecular structure.

The company’s founders — Lena Wu, Ph.D., CEO and President, and Erik Gentalen, Chief Technology Officer and Vice President, Intellectual Property — understood the production bottlenecks of protein characterization and detection. In fact, Gentalen was involved in developing the technology at the heart of the gold-standard technique used by the pharmaceutical industry to define the structural characteristics of biologics and biosimilars.

This technique is called imaged capillary isoelectric focusing (icIEF). It allows the separation of protein mixtures and is used in early biomanufacturing stages and for regulatory submissions of new products. Unfortunately, icIEF does not identify specific structural changes, which could have profound effects on the efficacy and toxicity of a biologic. Detecting those changes requires mass spectrometry, a powerful analytical technique used to identify and characterize the molecular structure of proteins. However, mass spectrometry requires a very complicated, intricate workflow that is constrained by time and resources, particularly when thousands of samples require analysis.

Living in the Customer’s “Footsteps”

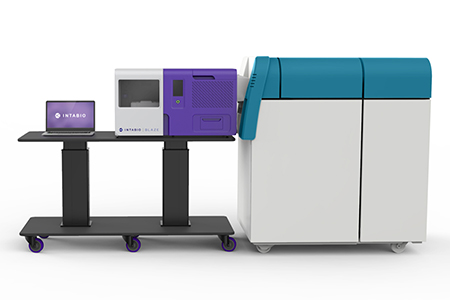

Inspired to solve these challenges, the Intabio team developed the Blaze™ System, an automated instrument that combines icIEF and mass spectrometry analysis into a single step and quickly processes multiple samples at a time.

Intabio’s Blaze System analyzes samples embedded in a microfluidic chip–based instrument system to provide rapid detection and identification of subtle changes in protein structures. (Intabio)

“Instead of requiring a room full of scientists and equipment and weeks of work, we can now do a completely automated analysis of a sample in 15 minutes,” said Wu.

The Blaze System includes a table-top instrument, a microchip-based consumable, reagent kits and analytical software. Blaze can detect precise changes quickly in the protein structure of a biologic or biosimilar. The current version can assess 25 samples at a time (15 minutes per sample), and the company is planning to offer microchips with greater capacity in the future.

By achieving the goal of “one instrument, one step,” Blaze delivers large productivity gains, generates significant savings in time and money, and helps pharmaceutical manufacturers make better decisions faster. Since its launch, Intabio, has collaborated with many of the world’s leading biopharma companies — such as Genentech, Merck and Pfizer — to ensure that Blaze is used widely during the development, regulatory approval and commercial manufacturing of biologics and biosimilars.

SBIR Fast-Track Grant to Support Commercial Development

Wu used the SBIR program to test out the feasibility of an innovation and then leveraged the grant to secure strategic partnerships to validate the technology. Having incorporated the SBIR grant into its overall financial strategy from the start, Intabio, also was able to get letters of support from potential customers and development partners to validate the commercial value of the Blaze System. In fact, Wu stated that the grant application process turned out to be a great way to help foster connections for the company that would be important in the future.

“It was really helpful for us to have the NCATS SBIR grant,” stated Wu. “Having gone through the peer-review process to win an SBIR Fast-Track grant offered great validation of the Blaze technology when we talked to investors about Series A funding. It helped us transition from the early research into developing a commercial product that pharma could use.”

The Intabio team achieved an impressive string of milestones throughout 2020 and remains enthusiastic about the company’s future. With the team’s steady progress, Wu continues to be responsible for defining the company’s vision and its corporate and business strategies. She also understands the importance of diversity in staff and the innovation fostered by women-owned companies today. As a female leader in a high-tech field, Wu encourages women to take advantage of incubator and networking programs, specifically those supporting and inspiring women entrepreneurs in the pharmaceutical world, to learn how to write successful grants and to start thinking about the overall financial strategy of their small business.

Fostering woman- and minority-led small businesses is a priority for the NCATS SBIR/Small Business Technology Transfer program, as well. To learn more, visit the NCATS’ Small Business Resources page.

January 2022 Update: The Acquisition of Intabio by SCIEX to Accelerate Drug Development

In April 2021, Intabio signed an agreement to integrate its Blaze System with the high-resolution accurate mass (HRAM) systems manufactured by SCIEX, an analytical technology company based in Framingham, Massachusetts. When coupled with the SCIEX HRAM system, the Intabio technology will enable drug manufacturers to streamline the detection and analysis of proteins and thus reduce the development time and production costs of biological drugs. The acquisition of Intabio is intended to help expand SCIEX’s product line through technology solutions to transform drug development and manufacturing.

“This acquisition creates a synergy of technology and scale to deliver solutions that eliminate many workflow bottlenecks our customers struggle with in biopharmaceutical drug development,” Wu said in a news release. “The Intabio team is excited by this acquisition and especially the ability to leverage SCIEX expertise and scale in global sales, support and manufacturing.”

The new workflow from Intabio and SCIEX is just one of the many new solutions for streamlining the current laborious and time-consuming approaches in the biopharma environment to characterize intact proteins.

Intabio has leveraged the NCATS SBIR grant and application process to move from testing feasibility to securing strategic partnerships to validating the technology and getting it to market faster. This latest milestone allows Intabio to develop new research tools and practical solutions that aid scientific discovery and deliver them to a wider market of researchers and clinicians.