NCATS Plate Washing Initiative Saves Money, Keeps Plastic Out of Landfills

High-throughput robots help researchers run screening experiments quickly and efficiently, producing results in one week that would take a scientist 12 years to conduct manually. At NCATS, these robots test thousands of potential drugs and drug combinations, environmental chemicals, and other experimental compounds to gain insights about a wide range of human diseases.

Back in 2010, staff at what is now the NCATS high-throughput screening facility were supporting the NIH Molecular Libraries Program, an NIH Common Fund initiative to identify small molecules that potentially could be used as biological probes to explore the basis of health and disease and further developed as drugs. At the end of each set of several thousand experiments, a staff member would remove a stack of plastic plates, each about the size of an index card and a half-inch thick.

“We’d throw them in here,” said Sam Michael, NCATS director of automation and compound management, pointing at a “carboy,” a waist-high blue plastic barrel used to collect chemical waste. “We were so busy, there were about 15 of these — I literally didn’t have enough room to work.” Michael also is the acting director of the NCATS Office of Information Technology.

The NCATS high-throughput screening facility is part of a laboratory where technicians work among tables and shelves stocked to the brim with equipment, plates and cables, leaving little space for more than a dozen barrels of waste. Michael knew there had to be a better way, and he found one: washing and reusing the plates.

Although that solution may sound trivial, it required persuading skeptical biologists that the plates could be cleaned thoroughly and rethinking the entire process of high-throughput screening. Today, experiments that once took thousands of plates can be run with just 40. This innovative idea has saved hundreds of thousands of scientific research dollars and dramatically reduced environmental plastic waste. And now, through a Small Business Innovation Research (SBIR) program grant from NCATS, a private-sector company is building on Michael’s work to develop and commercialize an automated plate cleaner.

“That Will Never Work”

Biologists are accustomed to working only with new materials. The high-throughput screening process involves sensitive experiments with tiny droplets of liquid; results could be completely thrown off by the merest speck of residue. Michael explained, “When I told biologists, ‘We are going to try to reuse your plate within an experiment,’ the first reaction was, ‘Get out of here; no way!’” But he inevitably convinced some of the researchers to try it.

If you held a three-by-five-inch plate in your hand, you would see a fine grid of tiny wells, each about as big around as a pencil lead. A plate the size of an index card holds 1,536 wells. Together, all of the wells in one plate hold about a tablespoon of liquid. That may seem small, but the wells are big enough for chemical reactions. Each one is like a tiny test tube, holding a tiny experiment.

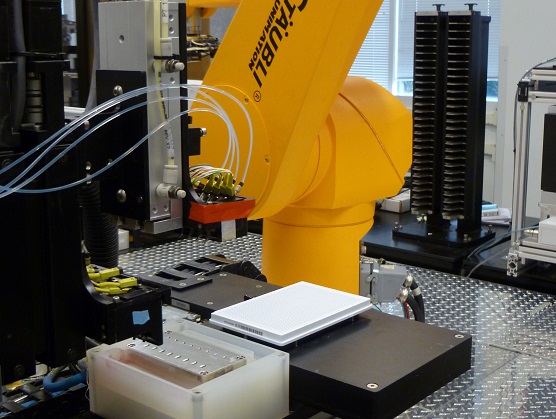

For high-throughput screening, a plate starts at a dispenser where small tubes spray the same substance into each well. Sometimes the plate wells hold living cells; during a visit on a late winter Wednesday, enzymes were on deck. Robotic arms transfer plates from one machine to another in assembly line style, with quick, efficient movements and the whirring sounds of precise motors.

The next stop for the plate is a machine with a rack of 1,536 tiny metal pins, one for each well. The pins act like a rubber stamp; the “ink” is a plate of compounds from a library of small molecules. The pins dip into the compound plate and then into the wells on the experimental plate, delivering one compound to each well. Each well gets a specific type of molecule that will interact with the enzyme, then the plates sit for a few hours. Finally, another machine takes a picture of each plate so scientists can figure out how each compound affected the reaction in each well.

A Clean Start

Following the traditional process, the plates become trash after imaging; they go to a landfill or incinerator, depending on the kind of waste they contain. But in the process Michael created, the next stop is cleaning. A dispenser alternates spraying deionized water and ethanol into the wells. After each spray, a row of aspirators, like the world’s tiniest vacuum cleaners, passes over the plate to suck the liquid out.

The cleaned plates are now ready to go back into the screening process. A plate is only reused within the same assay, or set of experiments. In practice, half of the plates for an assay are being cleaned while the rest are in testing.

Before starting each new assay, the NCATS team screens a few test plates to ensure cleaned plates give the same results as new plates. Sometimes the particular chemicals involved in the experiments just can’t be washed out, so the plates can only be used once, the old-fashioned way.

Once the assay is complete, the plates are always discarded, but the savings from reuse during screenings are huge. At about $10 per plate, an experiment that previously involved 2,000 plates at a cost of about $20,000 in plastic now costs $400 for those materials — 2 percent of the original expense.

So far, this method has saved NCATS almost half a million dollars and kept nearly 50,000 plastic plates from filling up chemical carboys. If that many plates were laid out end to end, they would be taller than Mount McKinley, the highest mountain in North America. The solution also has saved staff time from loading and unloading plates: four solid work weeks, Michael estimated.

Disseminating the Technology

The creation of the plate-cleaning technology aligns perfectly with the NCATS “3 Ds” approach to translational science. Michael developed an innovative solution to address a translational problem and then demonstrated that the approach worked and could save time, money and environmental waste. The next step was disseminating the technology to benefit the larger scientific community.

To reach that audience, Michael thought a small business might be able to scale up and expand the plate-cleaning technology. The Center’s SBIR program helps U.S. small businesses develop and commercialize new translational technologies. Michael worked with Lili Portilla, M.P.A., director of the NCATS Office of Strategic Alliances and SBIR program manager, to issue a contract solicitation for plate cleaning.

IonField Systems in Moorestown, New Jersey, responded to the solicitation and secured a Phase 1 SBIR contract from NCATS, then received a follow-on Phase 2 award. IonField already had developed a method called “plasma washing” to clean plastic tips used to move small quantities of liquid in biochemical research. To adapt this method to cleaning plates, the company put a final touch on the process that Michael had envisioned, adding a plasma wash after the rinses with ethanol and water. High-voltage electricity eliminates anything still attached to the plate and even scours off the top layer of the plastic itself.

The ultimate plan is to sell the cleaner to academic and industry screening facilities and offer a service for cleaning plates. The development of the cleaning process and service has turned what was once disposable waste into a reusable resource disseminated to other laboratories and pharmaceutical companies nationwide.

“This is exactly what the NCATS SBIR contract program is designed to accomplish,” Portilla said, “NCATS identifies a translational technology challenge that small businesses can address, commercialize and disseminate into the marketplace.”

“The SBIR program is a great mechanism, and I’m glad somebody can take this NIH technology and make it available to other scientists to speed their high-throughput screening activities,” Michael said.

The success of the plate-washing method demonstrates NCATS’ commitment to transforming the way that translational science is conducted. That commitment to innovation can generate much-needed byproducts as well — in this case, a method to reduce plastic waste in the research community.

Posted August 2015

January 2016 Update: Continued Growth and Expansion

To meet this new demand from the research community, IonField Systems has expanded from two employees in 2012 to five full-time staff and more than 20 subcontractors. The company reported more than 130 percent growth in 2015 and is on target to achieve even greater percent growth in 2016. IonField recently placed its first PlasmaKnife™ plate cleaner with a major pharmaceutical company, making the SBIR program’s goal of commercializing innovative new technologies a reality.

“Overall, this initiative has been a tremendous success, and it’s really due to NCATS’ SBIR program,” Michael said. “The funding mechanism enabled a small company to grow while helping to bring a completely new product to the market to address a need. The program worked exactly as intended by enabling a small business to engage in R&D to create jobs and commercialize a needed technology.”

Posted January 2016

January 2018 Update: Installation of First Commercial Release

AstraZeneca (AZ) and IonField System announced the successful completion of the PlasmaKnife Microplate Cleaning System beta test and the first installation of a commercial release. The PlasmaKnife initially will be used regularly at AZ’s Alderley Park Research Facility, and later at the new AZ Cambridge Research Facility.

“IonField is a great small business success story for NCATS,” Portilla said. “NCATS staff identified a translational problem common in drug development and IonField developed a very elegant solution to clean and reuse these expensive microplates.”

Posted January 2019